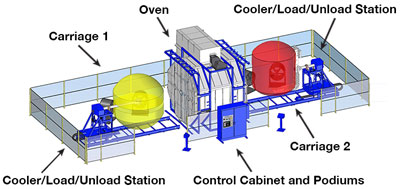

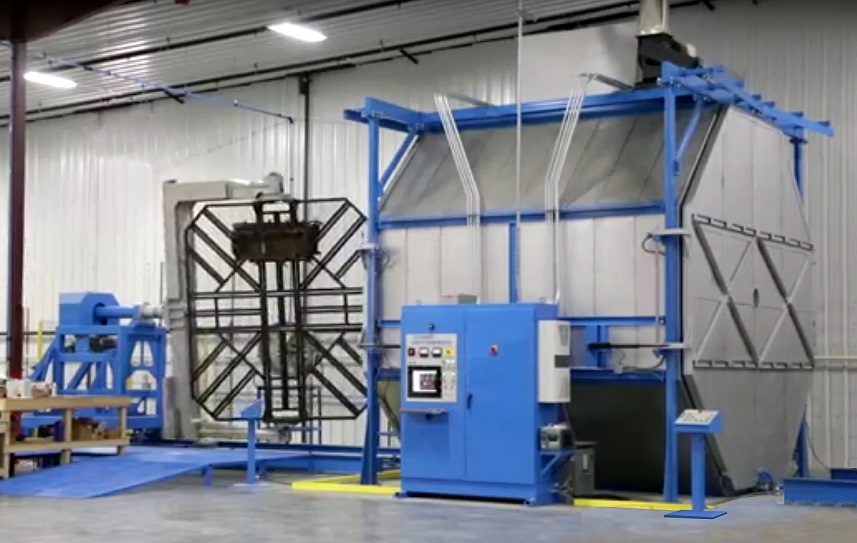

In-line shuttle-style machines are perfect for initial entry into the rotational molding market. The molder can start with a single arm and cart and expandable to meet increasingly specialized product needs. The shuttle’s modular concept provides machines that have from one to two arm/carts, both sharing a common oven. Shuttle carts index between the shared oven chamber and the individual cooling/service areas. Each arm has its own cycle programming. Shuttle machines can be purchased initially as a one-arm machine and later expanded.

The Ferry Shuttle range is an excellent system for prototyping new products or removing a part from your high production carousel machine. It is also beneficial when manufacturing large products. Though these machines are not as high production because at some point both arms will be out of the oven, which leaves the oven idle, they definitely have a purpose. These machines are also available in custom sizes to accommodate very large products.

|

| Models Available: | 7 |

| Number of Arms: | 1 or 2 |

| Swing Ranges: | 80" – 218" (2032 – 5500 mm) |

| Weight Capacities: | 1,500 to 7,500 lb (682 – 3,400 kg) per arm |

|

|